A laser level is an instrument…a laser level is a sensitive piece of equipment that is manufactured to exacting standards with fine tolerance, correct and accurate diodes, levelling systems and circuit boards in order to perform in harsh environments accurately and effectively every day.

An out-of-level job is a sure way to lose big money and is a contributor to costly reworks and shoddy workmanship. Therefore, all laser levels require regular service and calibration to perform within the accuracy tolerance and to give peace of mind to the laser level operator.

Given the many and varied types of lasers and the multiplicity of tasks that a laser level can be used for there is not a “one size fits all” answer to when and why a laser needs to be calibrated. The frequency of use and how much time the construction contractor uses the instrument and also if there are multiple tradesmen using the same device is also a consideration.

How often should a laser level be calibrated?

The general recommendation, and again this is only a rough guide, is that a line laser, rotary laser or pipe laser should be calibrated a minimum of every 12 months to maintain its accuracy.

However, if it is used frequently or daily such as a concreter with a rotary laser or a drainer with a pipe laser the laser level should be seen by a service technician a minimum of every 6 months and if in this situation it is used by multiple crew members a 3 month check is advisable.

If a laser is dropped, bumped or is on a tripod that is knocked over, it is advisable to take the unit to a service centre at the first possible opportunity and it shouldn’t be used without at least an on-site self-check. Most laser manuals have a detail on how to carry this out.

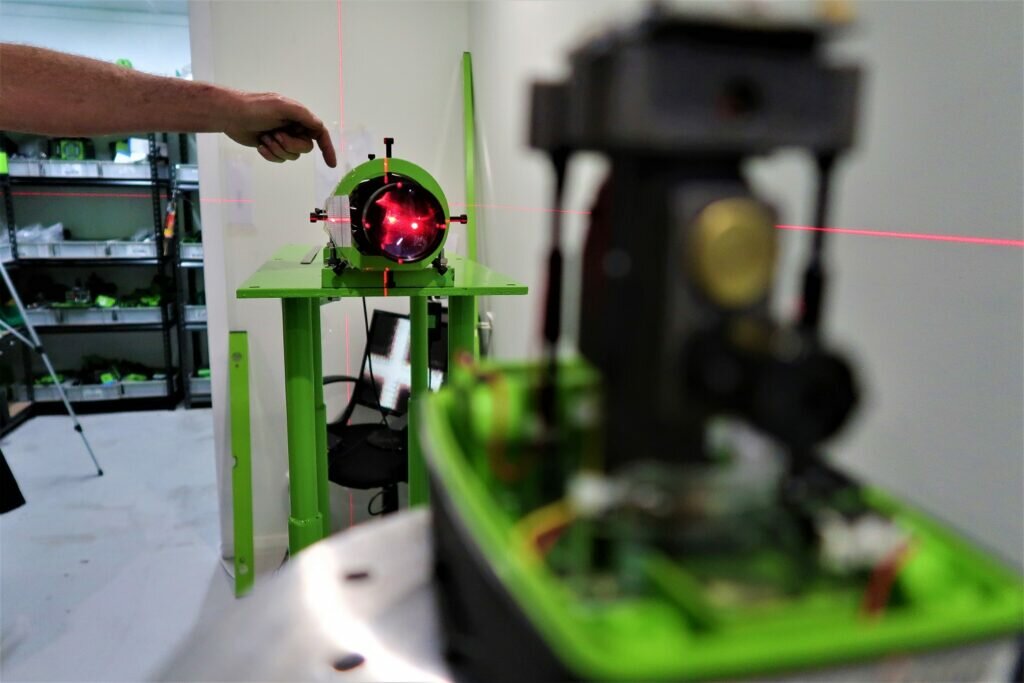

Most major cities have dedicated laser level service centres with the specialist collimators and equipment to calibrate a laser level to the manufacturer’s specifications and tolerances. Reputable brands such as iMEX have manufacturer-trained technicians who are expertly trained in checking, calibrating and repairing laser levelling tools.

Some lasers can’t be calibrated

Unfortunately, in the last decade there has been a number of cheaper brands or “no name” brands of laser levels and these may well do the job for the DIY-er who only uses a laser very infrequently.

However, most of these have fully enclosed housings that don’t allow for access for adjustment, circuit boards and diodes that are not suitable for day-to-day use and no replacement parts available. They may be cheaper up front, however without the ability to calibrate them or replace parts, they usually end up costing the contractor more in the long run.

When purchasing a laser level, it is important to make sure that the unit can be calibrated and if it is a reputable brand such as iMEX, designed for the professional tradesman, it will usually come standard with a pre-check calibration certificate and a service agent listing either in the instruction manual or on the brand’s website.

In summary:

- Purchase a reputable brand laser level that can be serviced and calibrated

- Monitor the frequency of use and set a service program according to the recommendations; 12,6 or 3 months.

- If a laser is dropped, bumped or falls, get it to a service technician at the earliest opportunity

Remember your reputation depends on accuracy and good laser level care with proper calibration and regular service is not worth compromising on.